End-To-End Product Development & Manufacturing Services

Emerging System is the leading regional provider of Engineering Design, Reverse Engineering, Material Analysis,

manufacturing, and Additive 3D Printing Solutions covering various products and services under one roof

Our Services

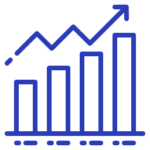

3D Metrology Services

Rely on our team of metrology experts for reliable, accurate and non-destructive measurement data for projects that are critical to your business. We use portable 3D scanning systems that are non- invasive and can easily capture data on-site for reverse engineering and inspection applications.

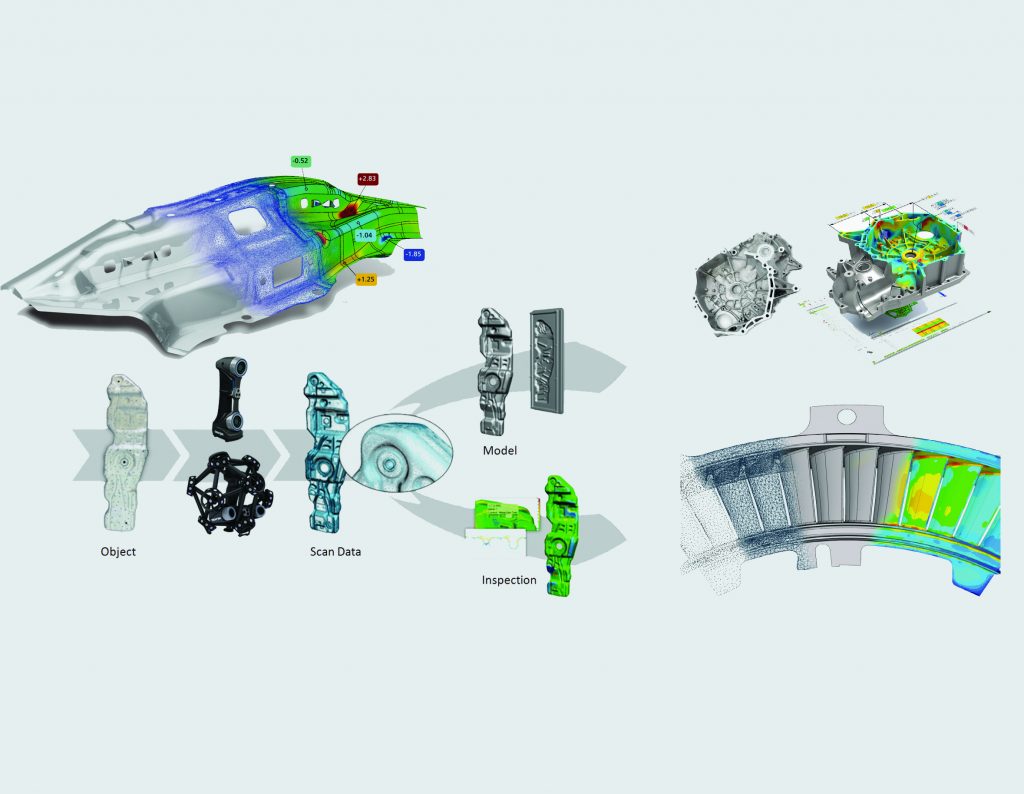

3D Designing & Analysis Services

Emerging System provides full support in CAD, CAE and CAM software from ideation to realisation of customers projects. The company’s team of engineers comprehend the customer’s requirements and presents rational designs and development solutions. A design brief is provided to the company’s customers along with concepts and prototypes.

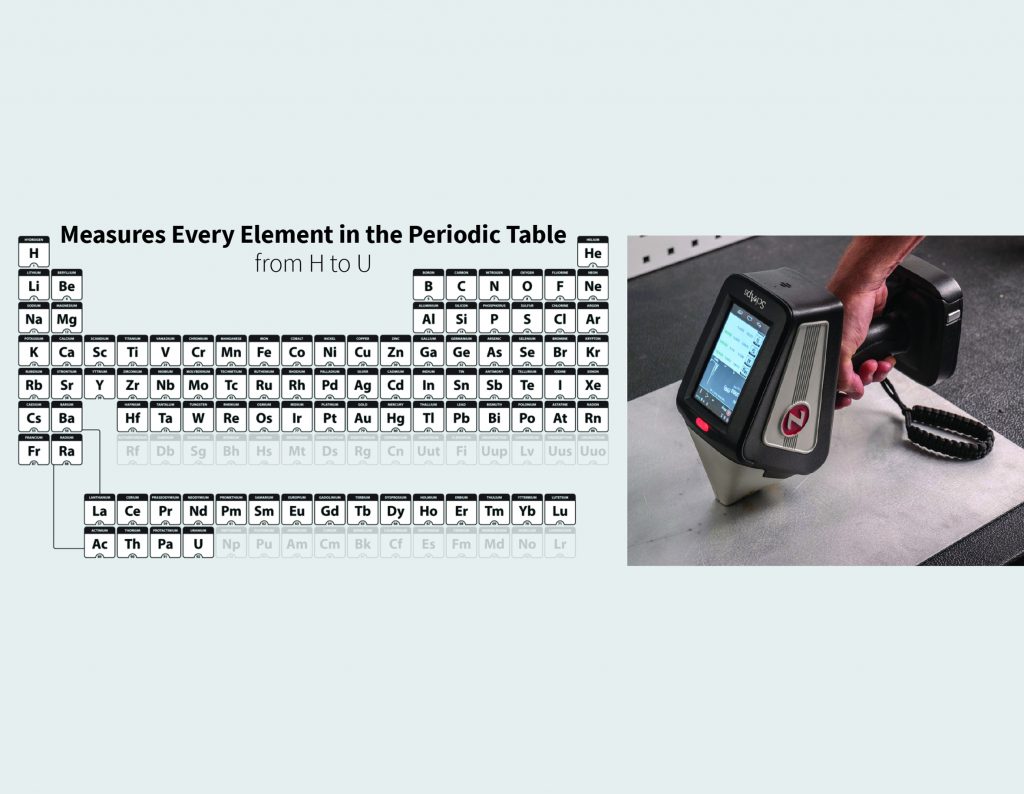

Material Analysis

Emerging System provides non-destructive testing methods to metals, composites, polymers, elastomers and resins to determine their potential properties, performance, strength, durability and resistance to corrosion and to ultimately help make certain that they are safe, compliant and fit for purpose in their end application.

Manufacturing Facility

Emerging System is fully equipped for production of PM and PIM (MIM/CIM) parts. Being a newly established setup, our main focus is on MIM Parts. In this process powder is typically mixed with polymer/ wax etc., called feedstock. The feedstock enables the molding process to be performed at fairly low temperature using slightly modified conventional plastic injection machines.

About Our Company

Creative vision and experience

Emerging Systems is a knowledge-driven custom manufacturing solutions provider that provides customer with full range of services from innovative design and engineering to product development and production using best in class quality control methods in a cost-efficient manner.

Emerging Systems Development/Reverse Engineering Services/ Solutions depending upon the requirement of the client.

Of all the services offered, Emerging System plays a flexible role as per Clients’ requirement. We can support you at any stage/level of your project till completion.

Unparalleled Offered Services

3D Metrology Services

Rely on our team of metrology experts for reliable, accurate and non-destructive measurement data for projects that are critical to your business. We use portable 3D scanning systems that are non- invasive and can easily capture data on-site for reverse engineering and inspection applications.

3D Designing & Analysis Services

Emerging System provides full support in CAD, CAE and CAM software from ideation to realisation of customers projects. The company’s team of engineers comprehend the customer’s requirements and presents rational designs and development solutions. A design brief is provided to the company’s customers along with concepts and prototypes.

Material Analysis

Emerging System provides non-destructive testing methods to metals, composites, polymers, elastomers and resins to determine their potential properties, performance, strength, durability and resistance to corrosion and to ultimately help make certain that they are safe, compliant and fit for purpose in their end application.

Manufacturing Facility

Emerging System fully equipped for production of PM and PIM (MIM/CIM) parts. Being a newly established setup, our main focus is on MIM Parts. In this process powder is typically mixed with polymer/ wax etc., called feedstock. The feedstock enables the molding process to be performed at fairly low temperature using slightly modified conventional plastic injection machines.